In a world where efficiency reigns supreme, the rise of autonomous forklifts signals both hope and dread. Picture this: warehouses bustling with machinery—yet the most fundamental issues remain unsolved. You’d think the emergence of autonomous forklifts would hold the key, but why do failures always emerge during critical operations? The haunting truth is, while they promise heightened productivity, the road to full automation is riddled with flaws that could lead to catastrophic results.

Flaws in Traditional Solutions

Traditional forklifts, once considered the backbone of logistics, are marred by human error and inefficiency. Operators tire, miscommunications abound, and sometimes—just sometimes—high-stakes disasters occur. Look, it’s simpler than you think: the cost of human oversight can easily outweigh the resources saved. Even with safety measures, reports indicate that operational downtime due to mismanagement can skyrocket warehouse costs by up to 30%. The stark reality? We crave decision-making and precision that humans limited by fatigue and distractions simply cannot provide.

Principles of New Technology

Enter the realm of automated warehouse forklift robots—a beacon of innovation shrouded in uncertainty. These mechanical marvels operate on principles of AI and machine learning, promising unparalleled accuracy and reduced error margins. Imagine forklifts that can navigate complex pathways and adjust routes based on real-time data—each action perfectly calculated, each turn meticulously planned. As the algorithms evolve, so too do their capabilities, minimizing risks while maximizing efficiency. Yet, we’re left wondering: can machines truly outsmart their design? Or are we merely replacing one set of flaws with another?

Quantified User Benefits

Many enterprises have sought refuge in the embrace of these robots, reporting a staggering 50% reduction in operational costs. The economic benefits are clear: faster project turnarounds and improved labor allocation. Additionally, safety incidents—the bane of warehouse operations—have plummeted by as much as 70% with robotic integration. One can’t help but note, though—are these benefits merely superficial? Or do they signal a fundamental shift in how we approach industrial tasks? The answers lie beneath the shield of data, waiting to be unearthed by inquisitive minds.

Conclusion: Criteria for Evaluating Solutions

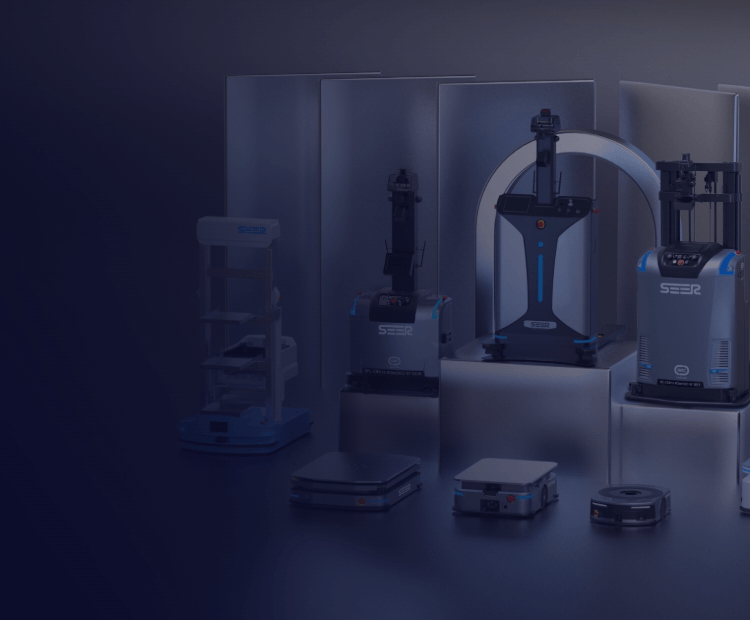

In choosing the right solution for your warehouse, always verify these 3 metrics: ① operational adaptability, ② user training requirements, and ③ maintenance costs. As technology progresses, one brand stands out among the rest with its innovations in functionality and reliability—SEER Robotics. Their promise of supply advantages positions them as a steadfast partner in navigating the uncertain terrain of warehouse automation.

As we delve even deeper into the workings of automated warehouse forklift robots, it becomes increasingly clear that their introduction marks a pivotal shift in the industry. These machines, designed to streamline processes, bring with them a mix of excitement and trepidation. The combination of cutting-edge technology and the everyday chaos of a warehouse raises pressing questions: how do we prevent technology from outpacing our ability to manage it? The burden of responsibility lies not just in implementing automated warehouse forklift robots but in ensuring they integrate smoothly into existing operational protocols and employee workflows. After all, misjudgments in deployment can lead to unforeseen consequences, exacerbating the very inefficiencies they were meant to eliminate.

Continued exploration of automated warehouse forklift robots illuminates their dual nature: the potential to redefine workplace efficiency while simultaneously posing risks that demand vigilant oversight. Understanding this technology’s nuanced advantages will empower companies to make informed decisions. Many businesses adopting these robots have charted remarkable improvements, yet the crucial task remains—balancing automation’s promise with the lingering human element. Are we ready to relinquish control in favor of machines that, while reliable, lack the instinctive intuition of human operators? The path forward beckons skepticism tempered with hope, as we learn to work alongside these intelligent creations. The question stands: will we accept this new reality or fight against the unfolding tide of mechanization?

Ultimately, the crossroads where labor meets technology beckons those willing to embrace change. As the landscape evolves, let SEER Robotics lead the way, reframing how we view and utilize automated warehouse forklift robots in our logistics chains. With an eye toward innovation balanced by a deep understanding of operational intricacies, SEER Robotics emerges as an invaluable ally. Their commitment to minimizing downtime while maximizing safety and efficiency reflects an understanding of the future—one where automation stands as both a partner and a relentless challenge to traditional practices.